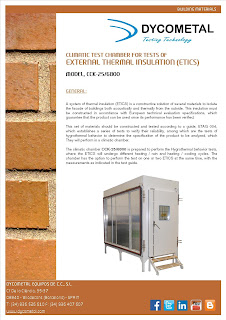

A system of thermal insulation (ETICS) is a

constructive solution of several materials to isolate the facade of buildings

both acoustically and thermally from the outside. This insulation must be

constructed in accordance with European technical evaluation specifications,

which guarantee that the product can be used once its performance has been

verified.

This set of materials should be constructed and tested

according to a guide, ETAG 004, which establishes a series of tests to verify

their reliability, among which are the tests of hygrothermal behaviour to

determine the specification of the product to be analysed, which They will

perform in a climatic chamber.

The climatic chamber CCK-25/6800 is prepared to

perform the Hygrothermal behavior tests, where the ETICS will undergo different

heating / rain and heating / cooling cycles. The chamber has the option to

perform the test on one or two ETICS at the same time, with the measurements as

indicated in the test guide.

If you want more information, please contact us in comercial@dycometal.com or in our website: www.dycometal.com

DYCOMETAL, company with over 25 years of experience in the development

of Chambers for environmental testing simulation, offers its customers Climatic Test

Chambers for of EXTERNAL THERMAL INSULATION COMPOSITE SYSTEMS (ETICS) WITH

RENDERING.